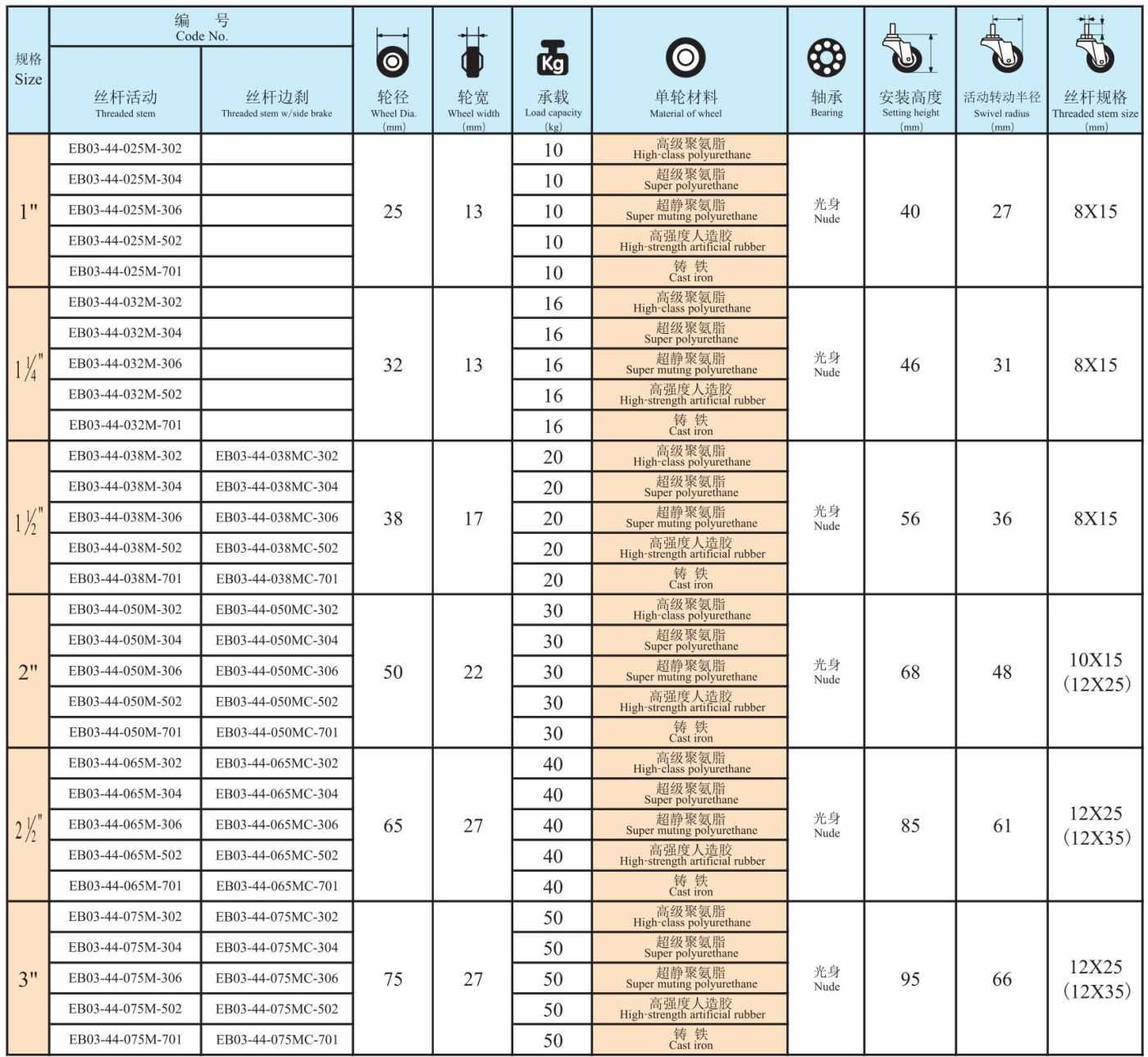

Factory made hot-sale China Elevator Castors - Light Duty Rigid Caster (PP, PU, PVC) EB3 Series-Threaded stem type(Chrome plating) – GLOBE

Factory made hot-sale China Elevator Castors - Light Duty Rigid Caster (PP, PU, PVC) EB3 Series-Threaded stem type(Chrome plating) – GLOBE Detail:

High-class PU caster

Super PU caster

Super muting PU caster

Cast iron cast

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing:

Workshop:

Advantages and disadvantages of industrial iron core polyurethane casters

Iron core polyurethane casters are made of polyurethane, glued to cast iron cores or steel cores or steel cores. They are quiet, slow and economical, and can be widely used in most operating environments. However, iron core polyurethane casters are not perfect.

Polyurethane casters have good load capacity, good wear resistance, anti-corrosion, and good anti-vibration performance, which can be regarded as the first choice of caster materials. Under normal circumstances, the size of industrial casters is between 4 and 8 inches (100-200mm). Polyurethane wheels are the best material, with superior wear resistance, a wide range of performance adjustments, various processing methods, wide applicability, oil resistance, and oil resistance. Ozone, aging resistance, radiation resistance, low temperature resistance, good sound permeability, strong adhesion, excellent biocompatibility and blood compatibility.

1. The performance can be adjusted in a large range.

A number of physical and mechanical performance indicators can be flexibly changed within a certain range through the selection of raw materials and the adjustment of formulas, so as to meet the unique requirements of users for product performance. For example, hardness is often an important indicator of users’ products. Polyurethane elastomers can be made into soft printing rubber rollers with a Shore A hardness of about 20, or hard rolled steel rubber rollers with a Shore D hardness of 70 or more. This is difficult for general elastomer materials, and it can be adapted to the needs of different users. Polyurethane elastomer is a polar polymer material composed of many flexible and rigid segments. As the proportion of rigid segments increases and the density of polar groups increases, the original strength and hardness of the elastomer will increase accordingly.

2. Superior wear resistance.

In the presence of water, oil and other wetting media, the wear resistance of polyurethane casters is often several to several tens of times that of ordinary rubber materials. Although metal materials such as steel are very hard, they are not necessarily wear-resistant; others such as rice hulling machine rubber rollers, coal preparation vibrating screens, sports ground race tracks, and dynamic oil seals for crane forklifts Rings, elevator wheels, roller skate wheels, etc. are also where polyurethane elastomers come in. One point that needs to be mentioned here is that to increase the friction coefficient of low- and medium-hardness polyurethane elastomer parts and improve the wear resistance under load, a small amount of aluminum disulfide, graphite or silicone oil can be added to this type of polyurethane elastomer. Lubricant.

3. Diverse processing methods and wide applicability.

Polyurethane elastomer can be molded by plasticizing, mixing, and vulcanizing process like general rubber (referring to MPU); it can also be made into liquid rubber, injection molding compression molding or spraying, potting, centrifugal molding (referring to CPU); it can also be manufactured Granular materials, like ordinary plastics, are molded by injection, extrusion, calendering, blow molding and other processes (referring to CPU). Molded or injection molded parts can also be processed by cutting, grinding, drilling, etc. within a certain hardness range. The diversity of processing makes the applicability of polyurethane elastomers very wide, and the fields of application continue to expand.

4. Oil resistance, ozone resistance, aging resistance, radiation resistance, low temperature resistance, good sound permeability, strong adhesion, excellent biocompatibility and blood compatibility. These advantages are the reasons why polyurethane elastomers are widely used in military, aerospace, acoustics, biology and other fields.

The disadvantage is that the internal heat generation is large, the high temperature resistance performance is general, especially the humidity and heat resistance is not good, and it is not resistant to strong polar solvents and strong acid and alkali media.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Factory made hot-sale China Elevator Castors - Light Duty Rigid Caster (PP, PU, PVC) EB3 Series-Threaded stem type(Chrome plating) – GLOBE , The product will supply to all over the world, such as: Iceland, Croatia, Zurich, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.