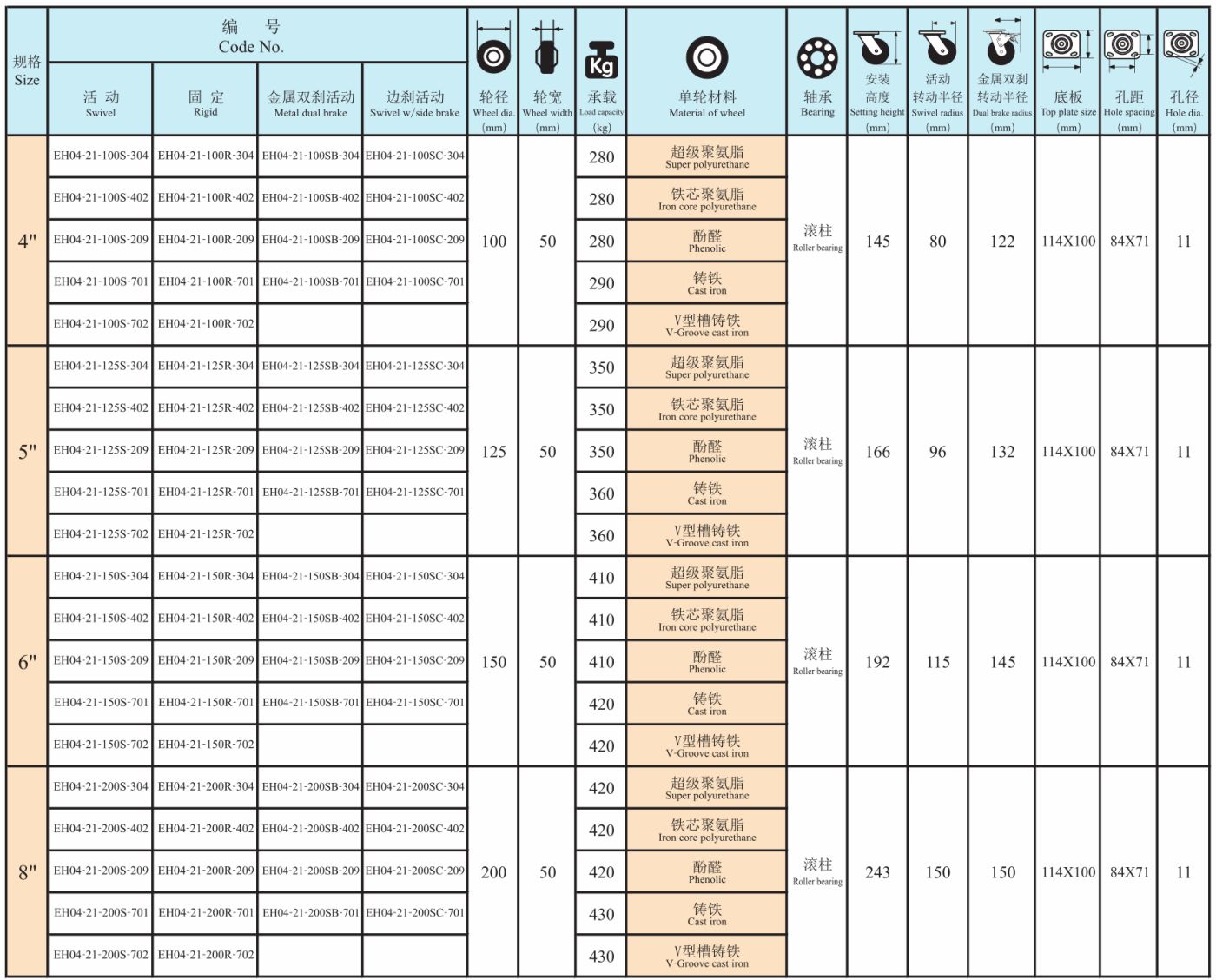

Wholesale Swivel Caster - 4/5/6/8 inch Industrial Heavy Duty Swivel /Rigid/Brake PU on Cast Iron Caster(Zinc-plating) – GLOBE

Wholesale Swivel Caster - 4/5/6/8 inch Industrial Heavy Duty Swivel /Rigid/Brake PU on Cast Iron Caster(Zinc-plating) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

How to choose heavy casters for trucks

1. Temperature requirements

Severe cold and heat may cause trouble to many wheels. For manual pallet trucks, it is best to choose heavy-duty casters that are compatible with the ambient temperature.

2. the use of venues

Choose suitable wheel materials according to the actual working conditions of the heavy-duty universal wheel:

- For use on rough ground, rubber, polyurethane or super synthetic rubber wheels should be resistant to wear and elasticity.

- When working under special high or low temperature, or the working environment has a large temperature difference, you should choose metal wheels or special high-temperature wheels.

- Where it is required to prevent the accumulation of static electricity, it is best to use a special anti-static wheel, or a metal wheel (if the ground does not require protection).

- When there are a lot of corrosive media in the working environment, wheels with good corrosion resistance should be selected accordingly. According to the requirements of the use environment for the adaptability of heavy-duty universal wheels, select the most suitable model.

3. Carrying capacity

Determine the load-bearing capacity of a single heavy-duty universal wheel according to the design load. The load-bearing capacity of heavy-duty universal wheels is the most basic and critical requirement for wheels, and a certain safety margin should be left.

4. rotation flexibility

- The high-precision ball bearing runs smoothly and flexibly, especially suitable for high-end equipment and quiet environment.

- Telling bearings made of high-quality DuPont engineering plastics are widely adapted to various corrosive media.

- The well-made needle roller bearings are still comfortable under heavy pressure.

- To protect the beautiful floor, please use soft rubber, polyurethane and super artificial rubber heavy duty casters.

- In order to avoid leaving unsightly wheel marks on the ground, please choose special gray rubber heavy-duty universal wheels, polyurethane wheels, super synthetic rubber wheels and other wheels without wheel marks.

5. other

According to various special requirements, suitable accessories can be selected. Manual hydraulic pallets, such as dust caps, sealing rings and anti-wrap caps, can keep the rotating parts of the casters clean, prevent the entanglement of various fibers, and make heavy casters remain flexible for long-term use; single and double brake devices can Effectively prevent the rotation and steering of heavy casters, allowing you to stay in any position.

Product detail pictures:

Related Product Guide:

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for Wholesale Swivel Caster - 4/5/6/8 inch Industrial Heavy Duty Swivel /Rigid/Brake PU on Cast Iron Caster(Zinc-plating) – GLOBE , The product will supply to all over the world, such as: Sri Lanka, Latvia, Austria, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.