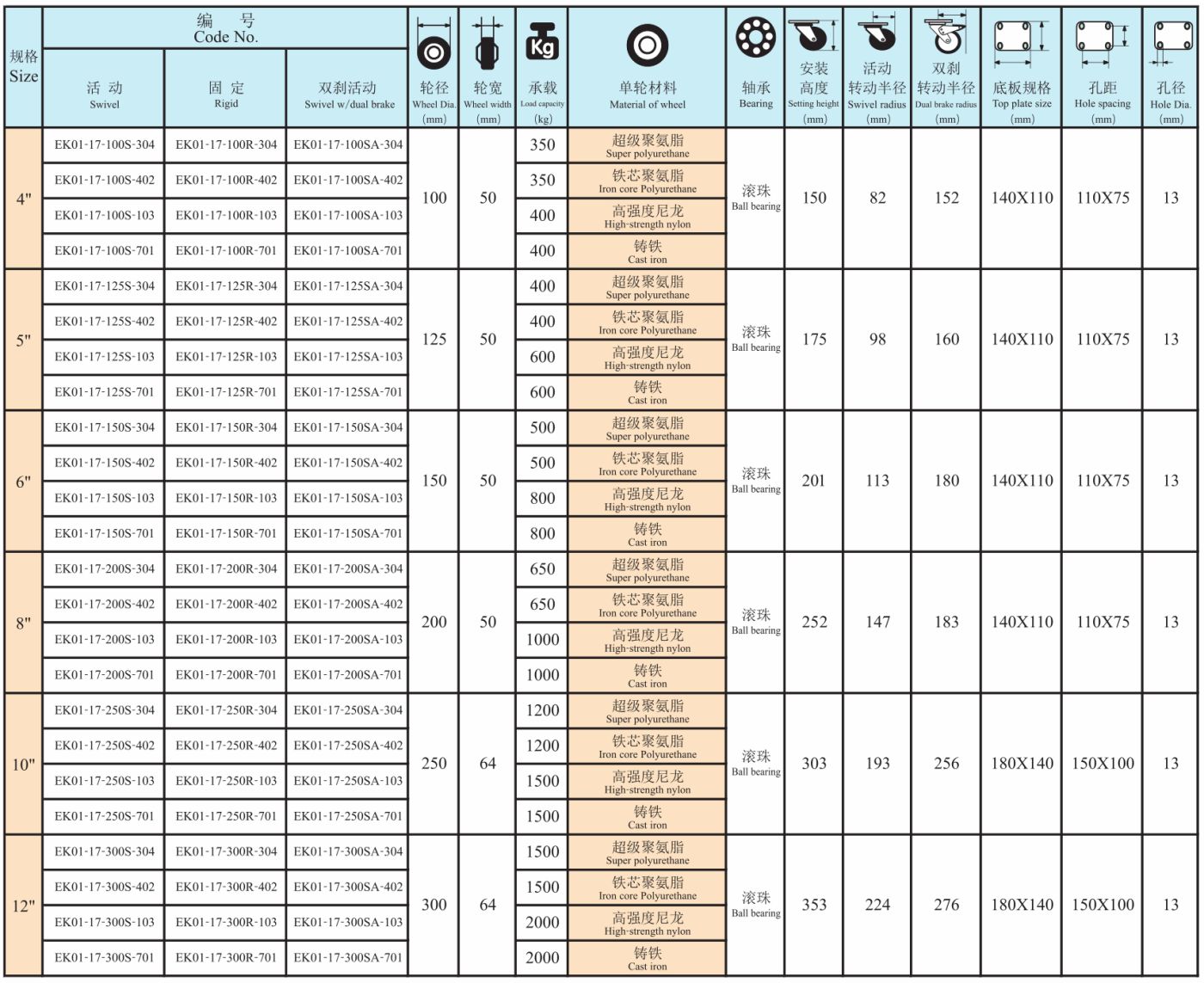

Extra Heavy Duty Top Plate type-Swivel/Rigid/Brake Nylon Caster(Baking finish)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

The universal wheel is composed of wheels, brackets and fasteners. The wheel can be said to be the core of the universal wheel, but this does not mean that customers can ignore other parts when maintaining the universal wheel. Today Globe Caster is here to tell you about the maintenance of universal wheels in addition to the maintenance of the wheels.

1. Maintenance of brackets and fasteners: If the movable steering is too loose, it must be replaced immediately. If the rivet in the center of the caster is fixed by a nut, it must be tightly locked. If the movable steering cannot rotate freely, check whether there is corrosion or dirt at the ball. If equipped with fixed casters, ensure that the caster brackets are not bent. Tighten the loose axle and nut and check whether the weld or support plate is damaged. Overload or impact will cause the bracket to twist, and the twisted bracket makes the heavy load tilt and press on the individual wheels and cause the wheels to be damaged prematurely. Therefore, the twisted bracket must be broken up or replaced.

2. Lubricant maintenance: add lubricating oil regularly, the wheels and movable bearings can be used normally for a long time. Applying grease to the friction parts of the axle, the seal ring and the roller bearing can reduce friction and make the rotation more flexible.

The maintenance of the universal wheels is important, but you can't lose sight of the other. In the process of maintaining the universal wheels, only the most comprehensive maintenance can ensure the flexible use of the universal wheels and extend the service life of the universal wheels.