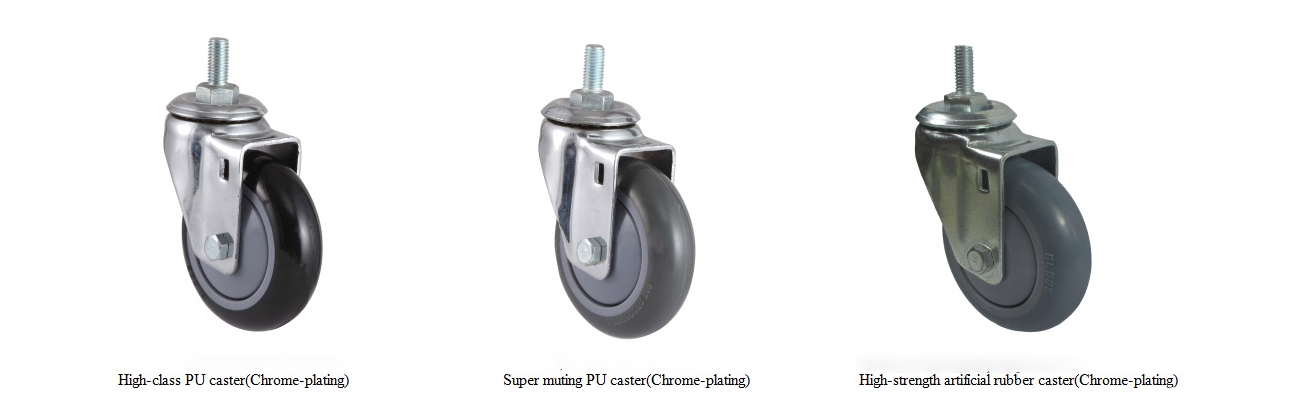

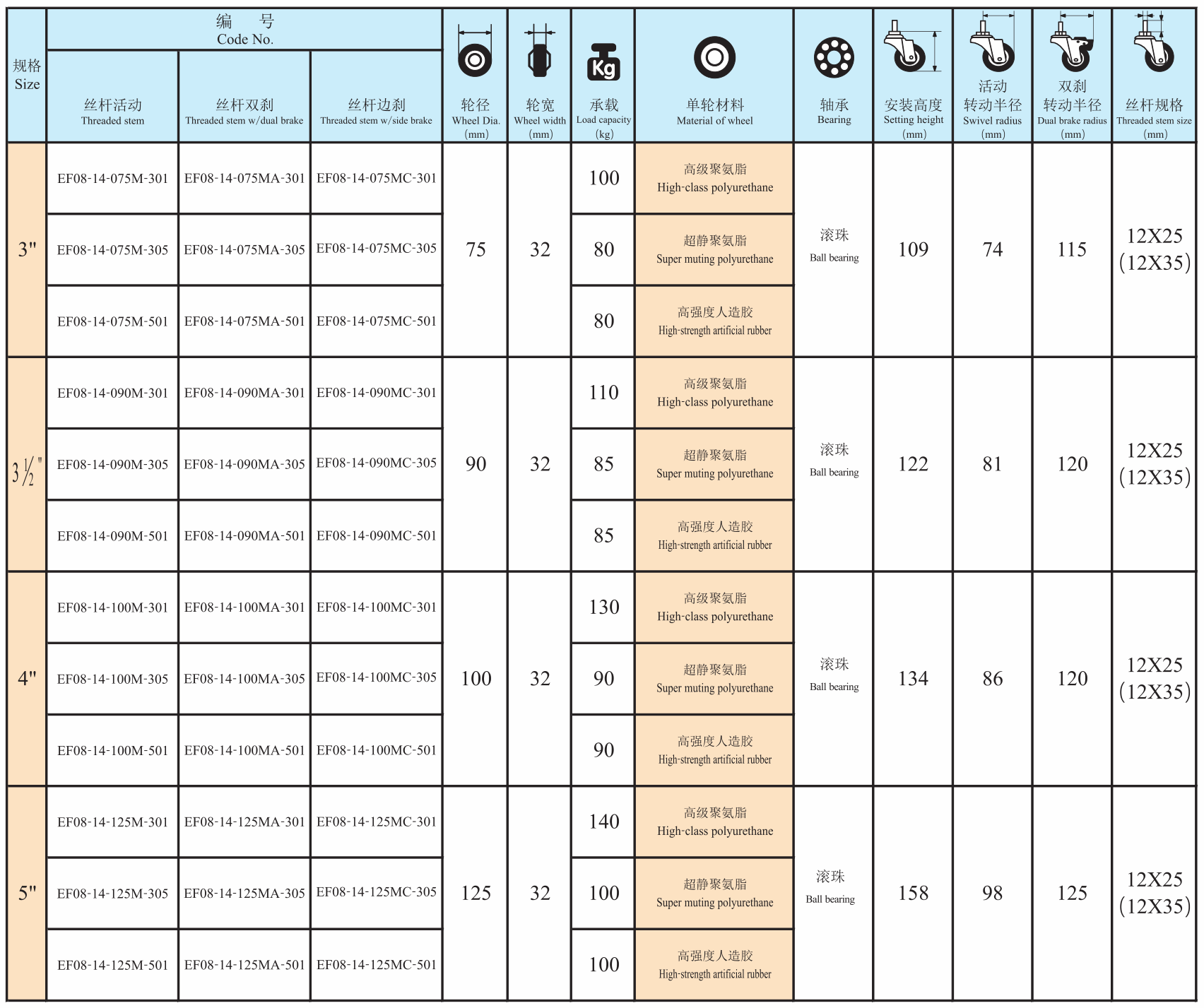

OEM Caster Industrial Equipment Chrome Plating Stem Castor China Exporters(Round)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

1. When using bowl buckle scaffolding, the bottom end must be covered with scaffolding, and side guard rails and body guardrails should be set on both sides;

2. When it is necessary to buckle the scaffolding, all the staff should be allowed to descend from the steel pipe scaffolding work platform to the road in advance, and then they can move;

3. After moving in time, step on the brake pedal of the wheel to lock the wheel;

4. During work, prevent the support frame from being subjected to unexpected level shocks and collisions;

5. It is forbidden to hang objects outside the support frame to avoid the support frame from tipping over due to heavy wheel weight;

6. At the construction site, it is not allowed to build a herringbone ladder on the work platform;

7. Two people should be prevented from moving from one side to the left and right of the herringbone ladder at the same time to avoid the steel scaffolding from tipping over;

8. The disassembly of steel tube scaffolding should be checked in all directions to see whether the connection of steel tube scaffolding, formwork support system, etc. comply with the structural regulations, and the disassembly work can only be carried out after the approval of the technical management process;

9. After the construction of the project, the steel scaffolding should be disassembled and assembled according to the upward and downward directions. The parts must be transferred one by one by manpower, or lifted one by one with ropes, or be disassembled in other special tools and methods that ensure that the steel scaffold will not be damaged. Install on the road surface, do not throw it down immediately.