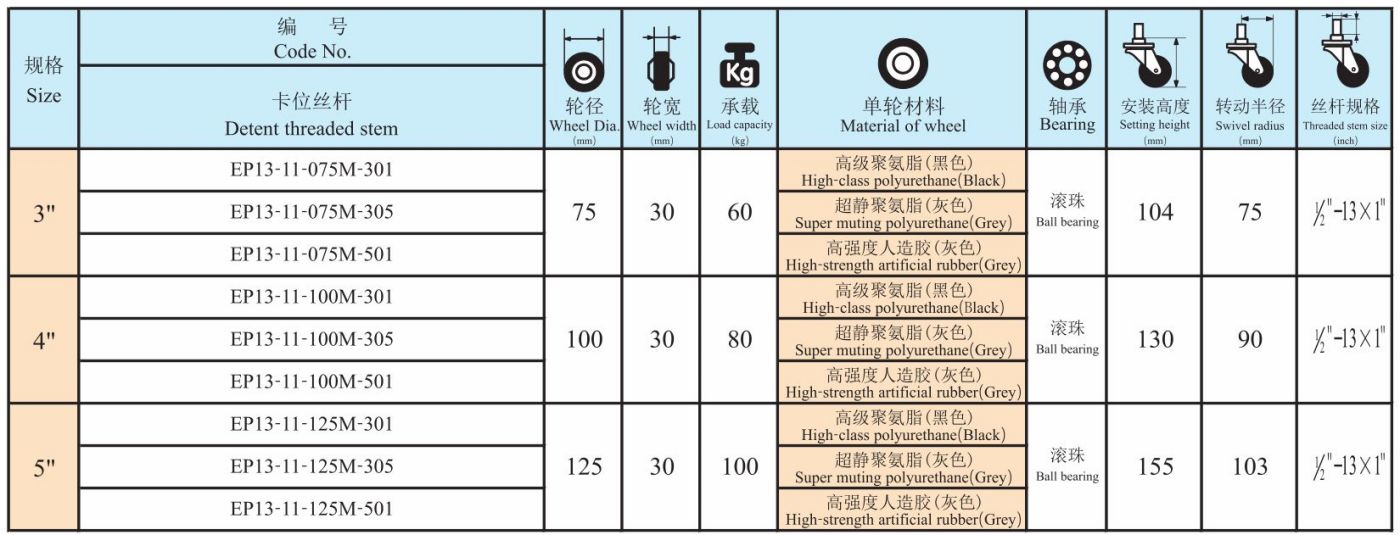

Threaded Stem TPR Wheel Supermarket Cart Caster ,EP13 Series Detent Threaded stem type(heat treatment fork)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

The required arbitration capacity is calculated as follows:

• T=(E+Z)/n*S

• T=The required load capacity of each wheel or caster

• E = the weight of the transport equipment

• Z=maximum load

• n=number of single wheels or casters required

• S = safety factor

In order to obtain the required load-bearing capacity of a single wheel or caster, the self-weight of the transport equipment, the maximum load and the number of single wheels and casters must be known. When four or more single wheels or casters are used, the load capacity of each single wheel or caster may be different.

Trolley is our common handling tool. To evaluate an easy-to-use trolley, the most important part is the industrial casters installed on the trolley. The easy-to-use trolley casters can make the trolley easier to push and light, and the trolley is less noisy and more durable.

So how to choose the right trolley casters?

1. To choose the load of the trolley casters, first consider the maximum load of your trolley. For example, the total load of your trolley is 1 ton. The trolley is generally equipped with 4 casters, but the load is divided equally by the 3 casters, because in the caster industry Inside, the force of the casters has a safety factor, and the casters do not necessarily receive the force at the same time during the pushing process, so the load is calculated according to the three casters. For example, for a trolley with a total load of 1 ton, a caster with a single-wheel load of more than 300KG should be selected.

2. The choice of the size of the trolley casters, the general size of the trolley casters is 4/5/6/8 inches, and the common wheel width is 40/48/50mm. The larger the wheel diameter and the wider the wheel width, the lighter and effortless the trolley will be. Of course, the larger the wheel, the higher the price. This requires us to choose according to the actual situation.

3. The choice of the material of the trolley casters: there are many kinds of materials for the casters. Different casters can be selected according to the different floor of the trolley. For example, the casters made of polyurethane can be used on the cement floor, and the epoxy floor can be used for the hotel cart dining car. Silent casters made of TPR material.

In summary, when choosing an industrial caster, you should choose the caster that suits you according to your own requirements, play the role of every penny, and reduce the cost of replacement.