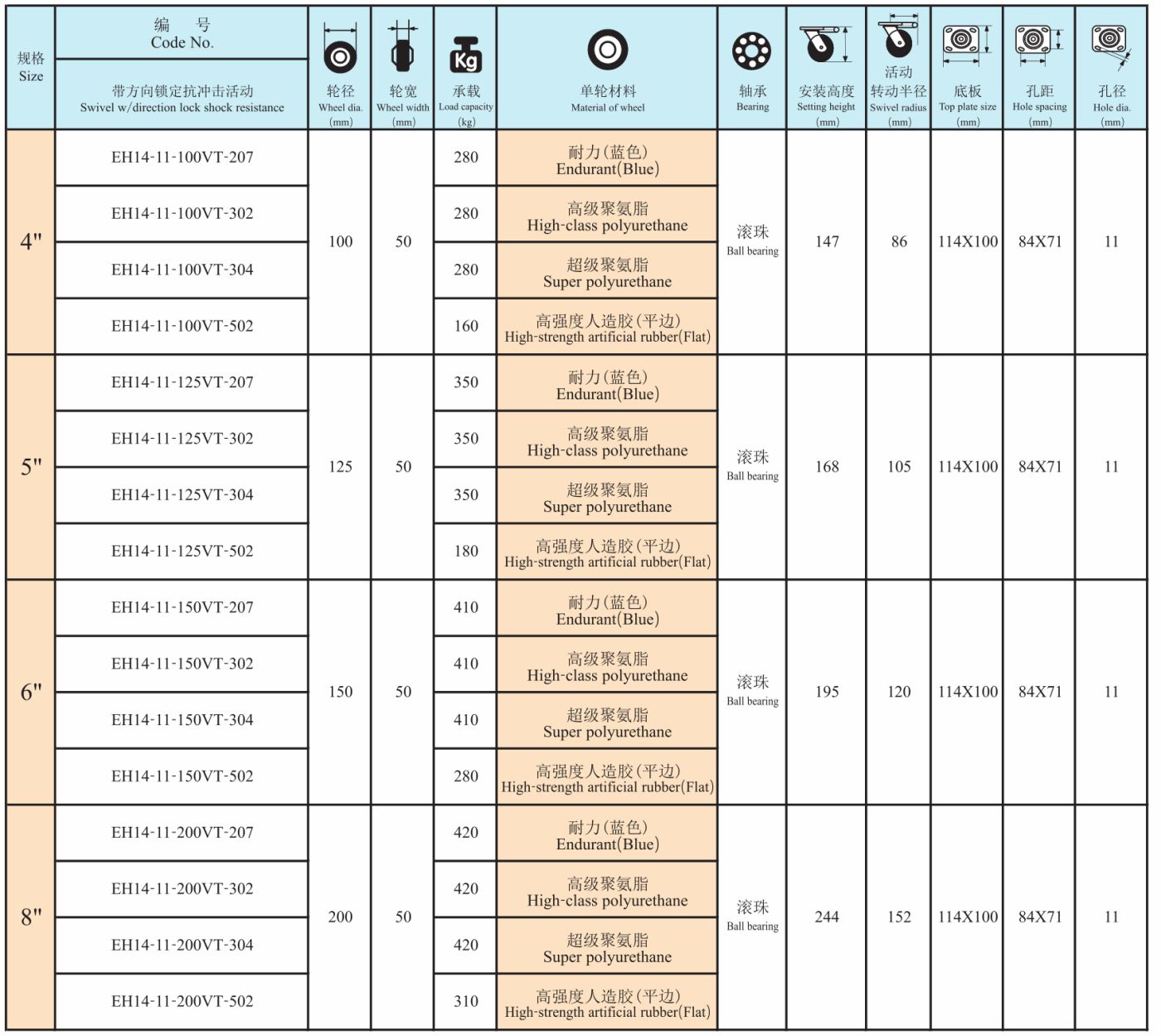

Industrial Caster Direction lock-shock resistance Swivel TPR/PU/Endurant Wheel(Zinc-plating)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

What should I do when the industrial casters are degummed or burst? During the time when I was out visiting customers, I met a customer who was doing machinery and equipment. He told me that they had used a batch of industrial casters before, and a large number of caster tire bursts occurred during the use of these wheels. There was no way. Use, there is no way to buy a new batch later. After hearing this case, I had a detailed understanding of its use, as well as a parameter of various aspects of this industrial caster, as well as a situation of this company. Only then did I realize that the industrial caster could not meet the requirements when running with a load. Because the customer’s device is of the often-moving-driven type, it is prone to degumming or bursting once the load-bearing driving time is too long.

Generally speaking, if the industrial casters used by customers are often moving and pushing, then we will sample the batch of industrial casters produced for load-bearing walking test before leaving the factory, or if the customer has special requirements, we will conduct relative tests. To prevent defective products and improve the quality of industrial casters, it is very important for an industrial caster manufacturer to inspect the product quality. When industrial casters are degummed or burst, the inspection of product quality should be strengthened.

Abrasion resistance test of industrial casters under load:

1. Test purpose: test whether the industrial casters produced meet the requirements and ensure product quality.

2. Ambient temperature: no special environmental requirements, ordinary indoor environment is fine.

3. Testing equipment: caster multi-function testing machine.

4. The height of walking obstacles: soft wheels are 3% of the wheel diameter, hard wheels are not, the obstacles and the wheels are at a 45° angle, and the two obstacles are placed alternately.

5. Timing of the test: The finished product after the single wheel is completely cooled after injection molding, and the bracket is riveted and assembled.

6. Tread hardness: TPU (85A-100A), TPE/TPR (65A-90A)

7. Test standard: Mainly execute according to customer standard requirements.

8. All products randomly sampled in normal production shall be loaded at 1.2 times the conventional load capacity and run continuously for 5 hours; the incoming material test shall be tested at 1.2 times the normal load capacity and run continuously for 8 hours, and the tires shall have no cracks, flaking and local excessive wear; All parts of the industrial casters are qualified without abnormal damage or permanent deformation that affects the use. The bearing (sleeve) rotates normally, without looseness and jams.

There are many benefits of industrial casters load-bearing walking test. It can detect the service life of this caster in long-term working conditions. In the same production process, the industrial casters produced by different materials can be tested and compared, and the quality of the caster materials can be distinguished. And bad. In the current profit-driven environment, in order to reduce their own costs, some industrial caster manufacturers use recycled materials (some recycled materials have been recycled many times, with poor toughness and easy disconnection). There are many burrs, and the more differences are poor transparency, dim color, poor elasticity, poor high temperature resistance, and easy to break. Therefore, these factors can cause the overall performance of industrial casters to deteriorate. As buyers and consumers, they should strengthen their awareness in this regard to better protect their own rights and interests.