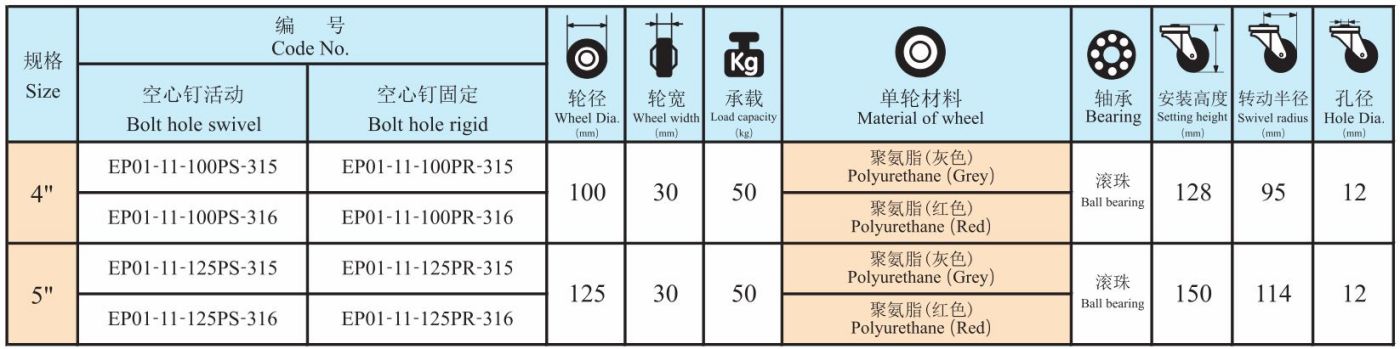

100mm PU Escalator Castor for Trolley EP2 Series Bolt hole type Swivel/Rigid three slices elevator caster

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

As the temperature continues to rise, bearing heating will occur during the application of industrial casters, and bearing burns may even occur in serious cases. Once encountered this situation, how to solve it? Globe Caster explains in detail for you.

The so-called bearing burn refers to that the race wheel, rolling element and cage of the bearing rapidly heat up during rotation until it is discolored, softened, welded and damaged. The main reasons for the burns of industrial caster bearings are as follows: 1. Excessive load (excessive preload) 2. The clearance is too small 3. The running speed is too high 4. The accuracy of the shaft and the bearing box is poor, and the deflection of the shaft is large. The bearing is poorly lubricated. Irregular lubricant may be used. Too much or too little lubricant is incorrect. Therefore, we should pay attention to related matters when using the product, and can not use it continuously. Therefore, in order to effectively avoid bearing burns, we must learn to pay attention to the bearing status and prevent bearing burns due to the above reasons.

Bearings are of great significance to casters. The degree of burns has a direct impact on the service life of the casters. If you want to maintain the good use of the casters, the majority of users must pay attention to the protection of the bearings during the use of the casters.