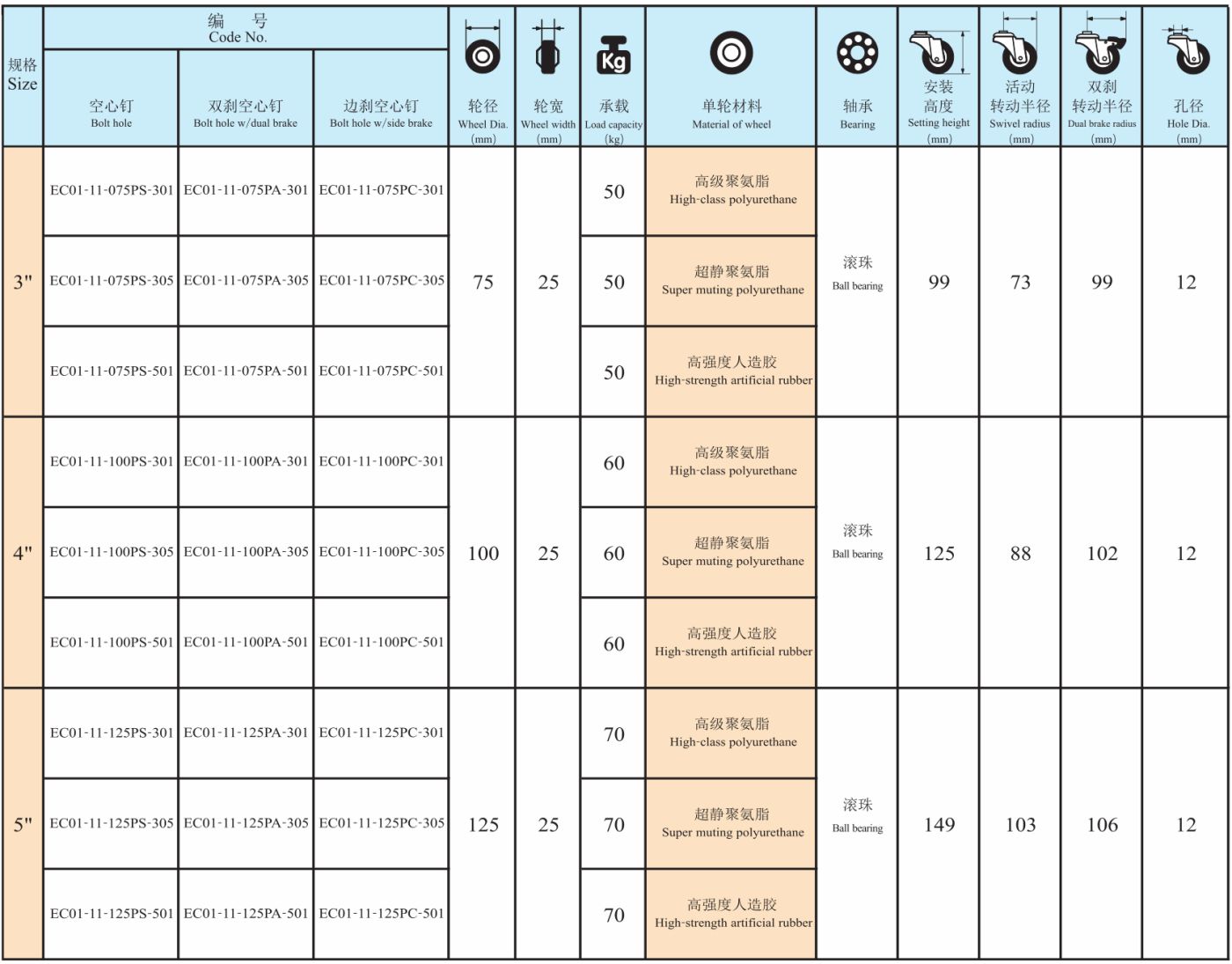

Swivel PU Caster Wheel Bolt Hole Type With Ball Bearing

High-class PU caster

Super muting PU caster

High-strength artificial rubber caster

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

It is also very difficult to trace the history of medium duty casters, but after people invented the wheel, it has become much easier to carry and move objects, but the wheels can only run in a straight line, which is very important for the change of direction when carrying large objects. It is still very difficult. Later, people invented wheels with steering structure, which are what we now call medium duty casters or universal wheels. The emergence of medium duty casters has brought a revolution in the age of people's transportation, especially moving objects. Not only can they be easily handled, but they can also move in any direction, which greatly improves efficiency.

In modern times, with the rise of the industrial revolution, more and more equipment needs to be moved, and medium duty casters have become more and more widely used all over the world. All walks of life are almost inseparable from medium duty casters. In modern times, with the continuous development of science and technology, the equipment has become more and more multifunctional and high-utilization, and medium duty casters have become indispensable parts. The development of medium duty casters has become more specialized and has become a special industry.

The structure of the medium caster is made up of a single wheel mounted on a bracket, which is used to install under the equipment so that it can move freely. Medium casters are mainly divided into two categories:

1. Fixed medium casters: The fixed bracket is equipped with a single wheel, which can only move in a straight line.

2. Movable medium casters: The 360-degree steering bracket is equipped with a single wheel, which can drive in any direction at will.

Industrial medium casters have a wide range of single wheels, which are different in size, model, and tire surface. Choosing the right wheel is based on the following conditions:

- Use site environment, the product's load-carrying working environment contains chemicals, blood, grease, engine oil, salt and other substances.

- Various special climates, such as humidity, high temperature or severe cold

- Requirements for shock resistance, collision and driving quietness.