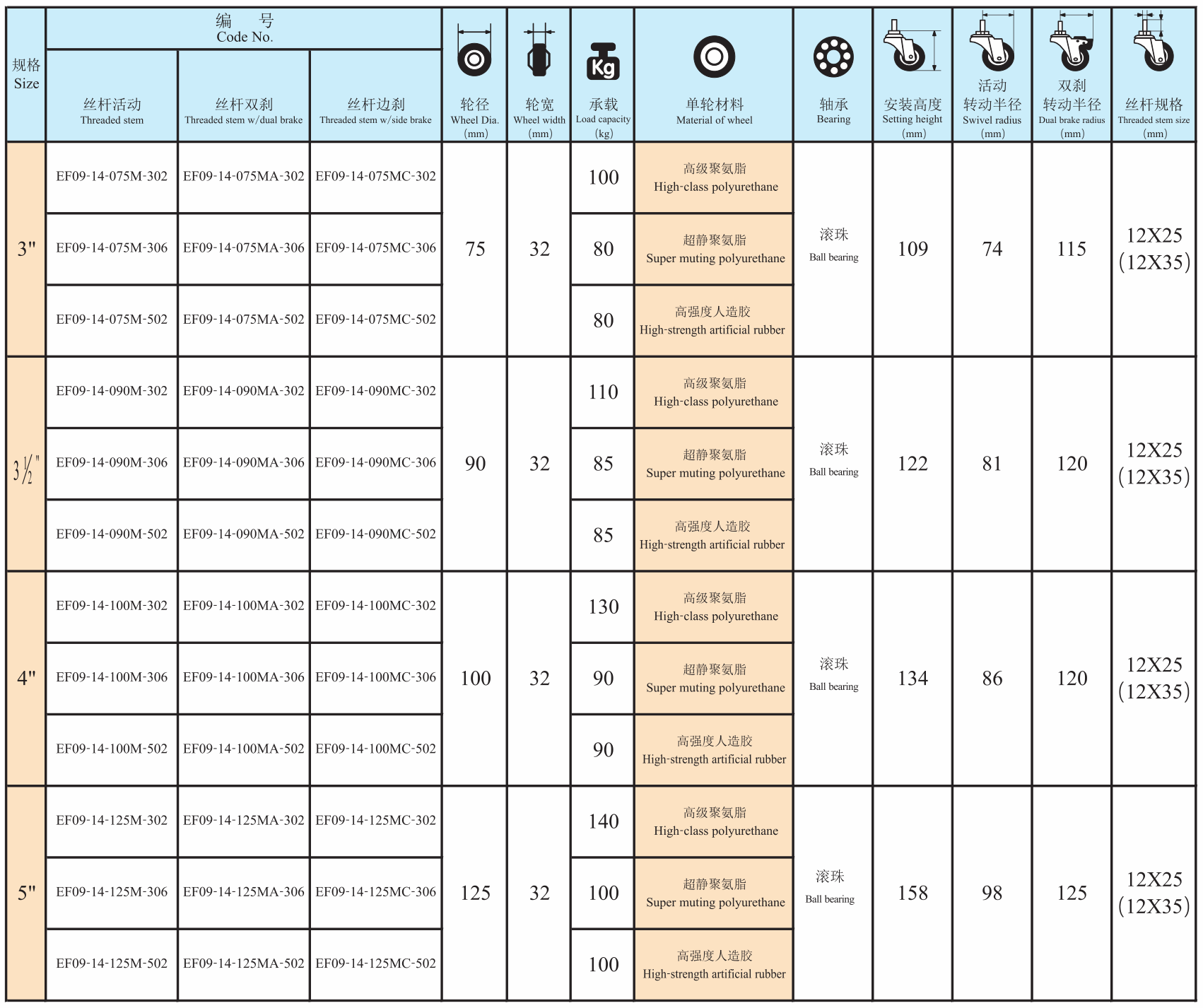

Medium Duty Chrome Plating Flat PU Trolley Caster Stem With Brake

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

The application scope and frequency of industrial production casters are becoming more and more common nowadays. Compared with other caster products, the product design of industrial production casters and their load-bearing scope are more delicate and professional. , Caster is a general term, and with the increase in the demand for various caster products in the sales market, the customer segmentation trend of caster products is gradually becoming obvious. Let's take a look at how to choose industrial casters.

First of all, when we consider the purchase of caster products, we must be able to consider the actual situation. Even if we choose industrial casters, we must be able to choose according to this level when considering this type of product. It seems to be ordinary spare parts, but the application function is not to be underestimated. The design of industrial production caster products must meet the relevant regulations for the product.

Including the requirements on the appearance, all the parts of the industrial production casters that meet the standards should not have disadvantages that affect the application. This is also one of the problems that suppliers must pay attention to when considering the purchase of industrial production casters. Industrial production Polyurethane casters and all-iron casters are more common for casters. The latter is very easy to be oxidized by air, so a reasonable method must be selected to avoid rust.

In addition, the matching of parts on the surface of industrial caster products can definitely be very good, including the surface color of the parts should be symmetrical, which is also one of the key main parameters to consider the quality of the product, various parts can meet the requirements of the design plan, such as wheels , The support frame should be able to ensure flexible rotation under the condition of detection, without jamming and loose conditions, and the installation of the wheels should be firm.

In the case of industrial production casters, most of them are all considering the application requirements of the machinery and equipment. Generally, all fixed wheels and universal wheels are purchased together. Then everyone must consider the brake system when considering the caster products. The characteristics of the equipment, the size of the gap in the middle of the support frame must be strictly controlled, and the design of the key specifications of the casters and wheels must be strictly in line with the main parameter design requirements.

Temperature regulations are also one of the key elements that must be fully considered. If casters used in weaker natural environments have very large restrictions on the selection of materials, casters of general materials cannot give full play to the actual effect. According to the feedback from the sales market, it seems , Polyurethane casters can be used in natural environments with relatively limited temperatures.

In addition to the above key points of purchase, the quality of industrial casters must also be evaluated according to the caster system driving force test, the horizontal force negative pressure test and its conversion to the system driving force test, etc. Generally speaking, the more the load category is For large casters, the necessary thickness of the caster support frame is also thicker. For example, if the goods are transported more frequently and the sandbag leggings are larger (the load range of each caster is between 150Kg and 700Kg, it is more suitable for 5 to 6mm stamping die hot forging and Single and double row steel ball side frames by electric welding).

Although there are many manufacturers that can give industrial casters products today, not all of them are worthy of selection. Whether you are buying industrial casters or other products, it is undoubtedly correct to shop around. At the same time, reliable manufacturers can also provide customers with sound after-sales maintenance services, so that customers can purchase products at ease.