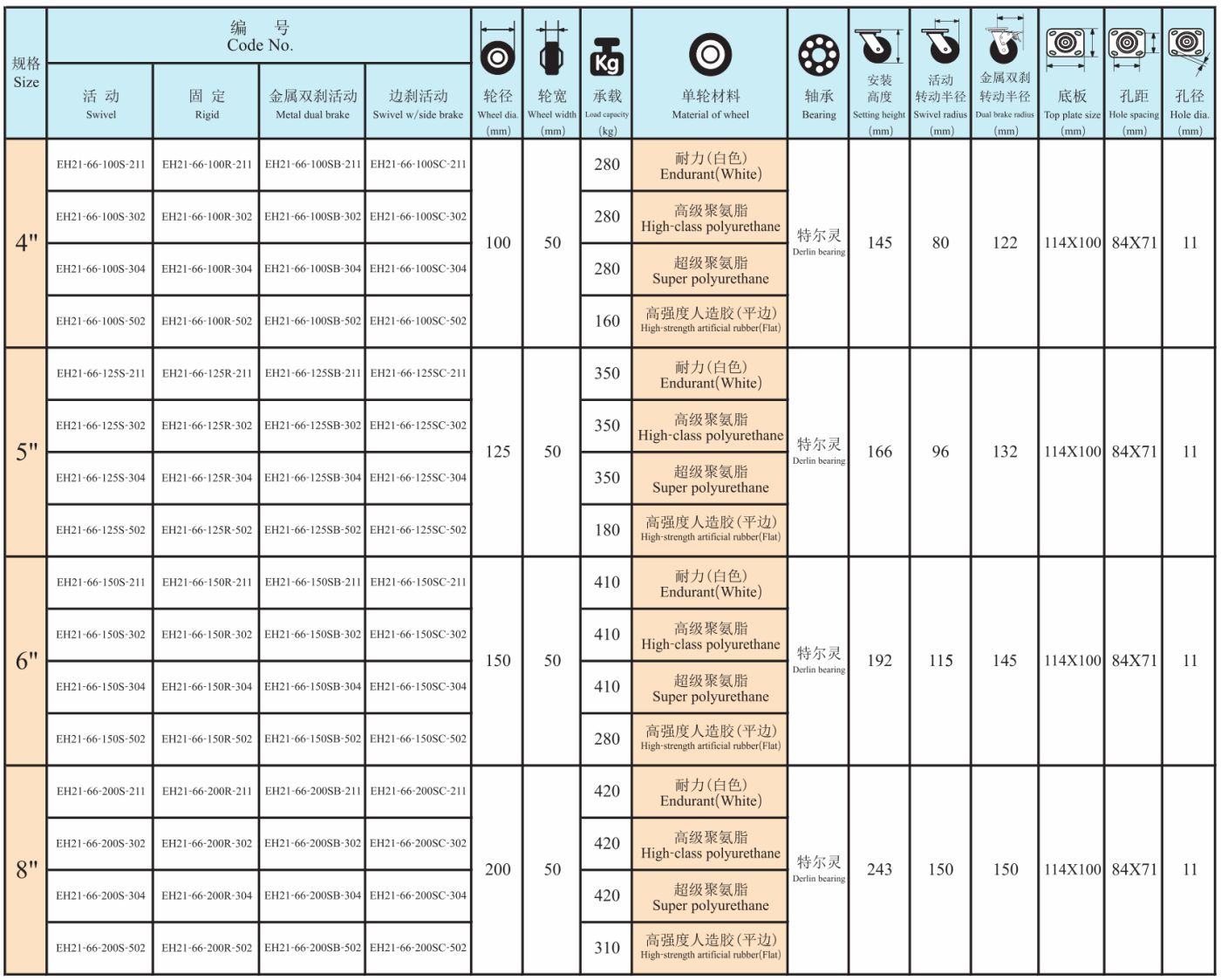

Industrial Endurant Caster With Derlin Bearing Swivel/Rigid/Brake Types

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Heavy-duty casters are used to move heavy equipment. Therefore, the wheels of heavy-duty casters generally use hard-tread single wheels. Such as nylon wheels, cast iron wheels, forged steel wheels, hard rubber wheels, polyurethane wheels, and phenolic resin wheels are ideal choices. Among them, forged steel wheels and polyurethane caster wheels are especially suitable for wheels matched with extra-heavy casters.

1. Caster impact load: the instantaneous load capacity of the caster when the equipment is impacted or shaken by a load.

2. Moving load of casters: the carrying capacity of the steering casters when moving. Also called dynamic load. The dynamic load of steering casters varies depending on the factory's specifications and the implementation of test methods. It is also different due to different information on the wheels. The key is whether the structure and quality of the bracket can resist impact and earthquake.

3. Caster turning radius: refers to the horizontal distance from the vertical line of the center rivet to the outer edge of the tire. Proper spacing allows the steering casters to turn 360 degrees. Whether the turning radius is reasonable or not directly affects the service life of the steering casters.

4. It is installed under the equipment with a steering caster structure to make it move freely. The steering casters are mainly divided into two categories:

(1) Casters that can only move in a straight line are called fixed steering casters.

(2) You can drive in any direction at will. The 360-degree steering bracket is equipped with a single wheel, which is called a movable steering caster.

5. Caster bracket steering center distance: refers to the horizontal distance from the vertical line of the center rivet to the center of the wheel core.

6. Movement flexibility of casters:

(1) On a stable ground, the factors that affect the flexibility of the steering casters include: the structure of the bracket and the choice of bracket steel, the size of the wheel, the type of wheel, and the bearing. The bigger the wheel, the better the driving agility. Hard and narrow wheels require less effort than soft wheels with flat sides.

(2) But on uneven ground, soft wheels can better maintain equipment and absorb shocks.