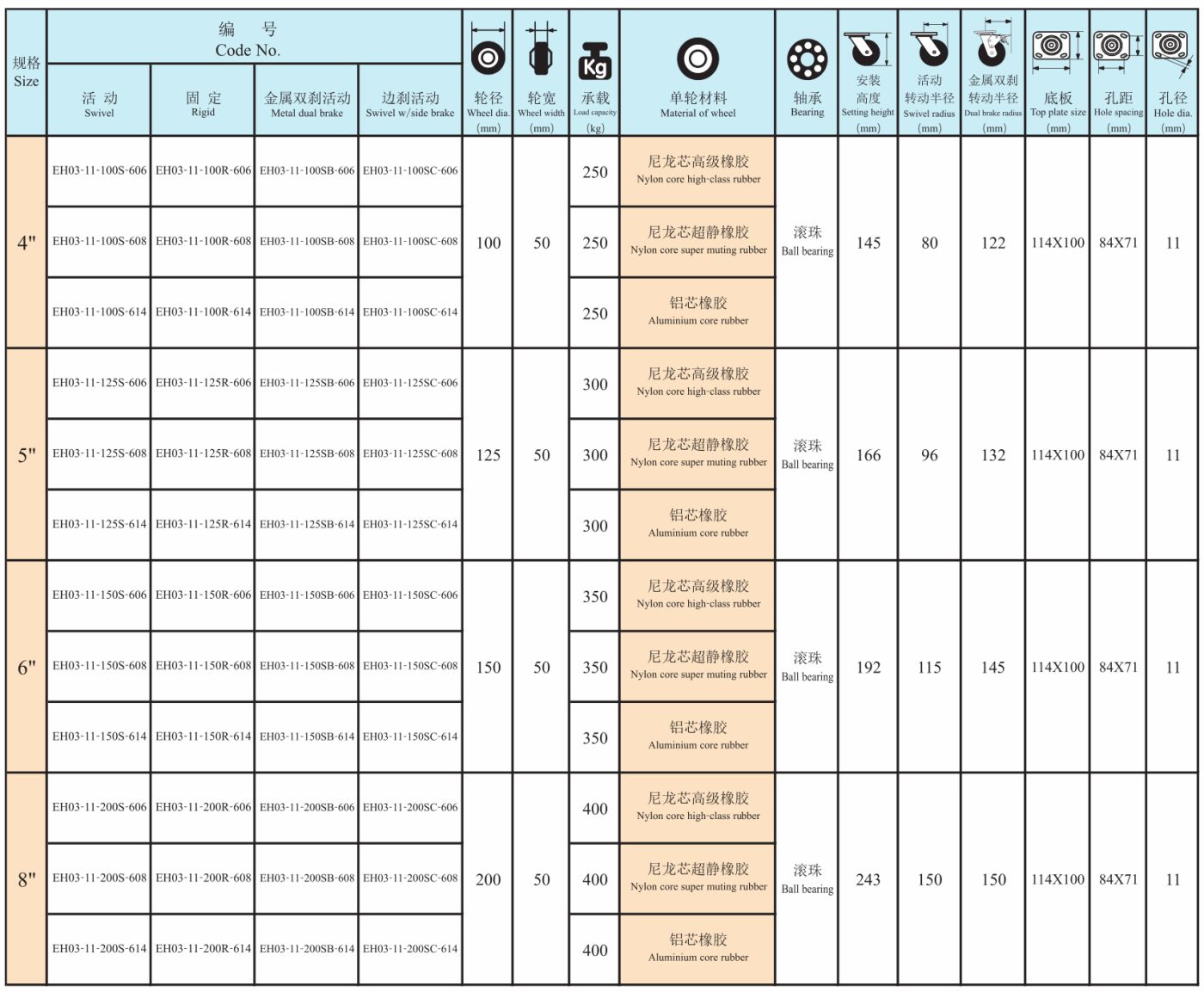

Heavy Duty Double Ball Bearing Rubber Caster Wheel With Swivel/Rigid/Brake Type(Zinc-plating)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

In the application process of casters, we will find that the same caster products, some are easy to rust, some are difficult to rust. Why does this phenomenon occur? What are the factors related to caster rust? Globe Caster is here to learn about the secrets of rusty casters with everyone.

Through experiments, we found that: water and oxygen are the reasons that make the casters easy to rust. Water alone will not make the casters rust. Only when the oxygen in the air is dissolved in the water, the chemical reaction between the oxygen and the casters in a watery environment will produce something called oxide casters, which is caster rust. . Caster rust is a reddish-brown substance. It is not as hard as casters and can easily fall off. After a caster is completely rusted, the volume can be increased by 8 times. If the caster rust is not removed, this spongy caster rust is particularly easy to absorb water, and the caster will rust faster.

In this way, we can take measures to effectively prevent the casters from rusting. Casters in wet places are more prone to rust than casters in dry places, because casters in wet places are more prone to contact with water than casters in dry places. Painted caster products are not easy to rust because the paint has the effect of isolating air and water.

If you want to reduce the rust of the casters, you can start from the conclusion of the experiment and cut off one of the conditions of rust arbitrarily. If paint is applied on it, the contact between the caster and the air is cut off. When some caster products, such as kitchen knives, are used up and placed in a dry place, the contact between the caster wheels and water can be cut off, thereby preventing the caster products from rusting.