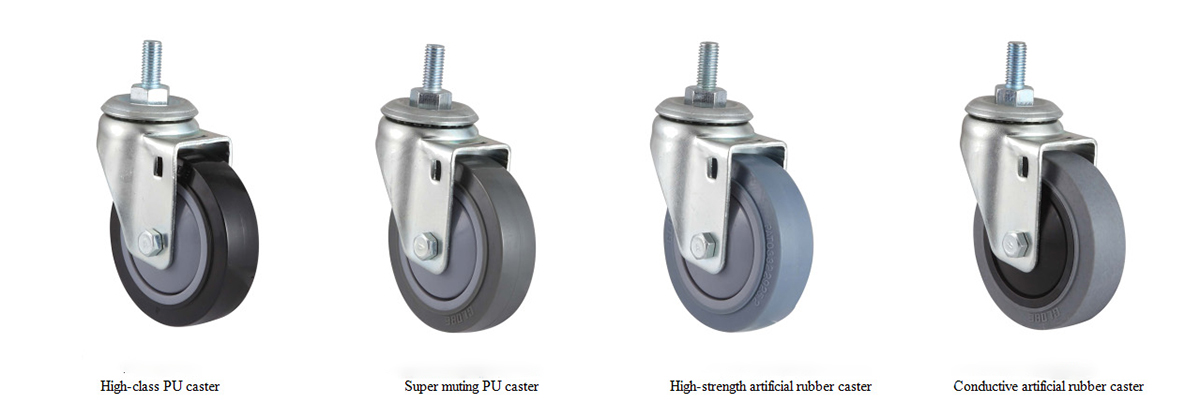

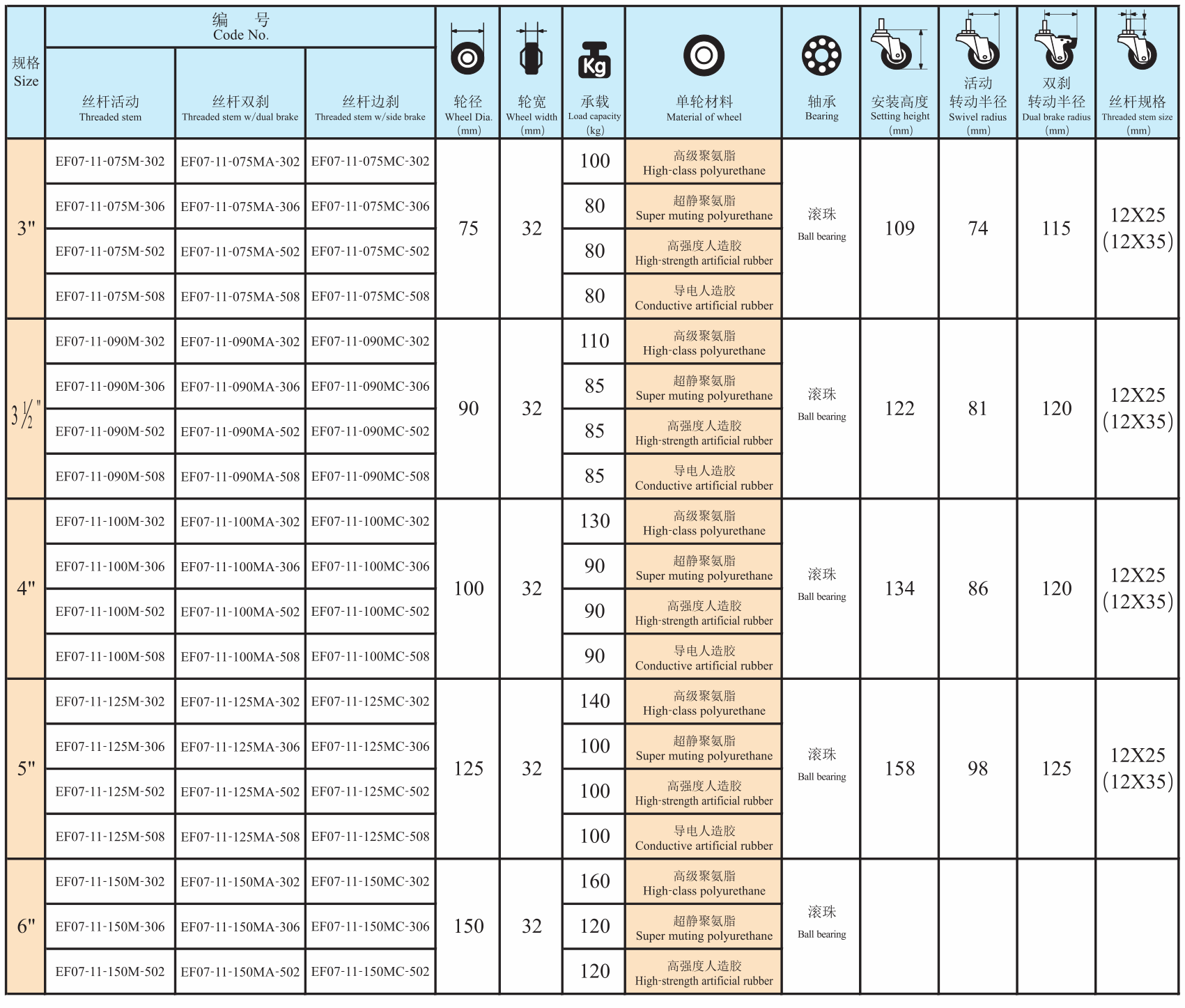

Polyurethane Casters Flat Industrial PU Trolley Castor Stem With Brake

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

In order to extend the service life of casters, it is necessary to do regular maintenance work on casters.

1. Visually check the wear of the wheels: the wheel rotation is not smooth and the rope and other sundries are related.

2. Inspection of brackets and fasteners: Too loose or too tight of the casters is another factor. Replace the damaged wheels. After checking and replacing the wheels, ensure that the axles are tightened with lock washers and nuts. Because the loose wheel axle will cause friction between the spokes and the bracket and jam, replacement wheels and bearings should be provided to avoid production downtime. If the movable steering is too loose, it must be replaced immediately. If the rivet in the center of the caster is fixed by a nut, ensure that it is tightly locked. If the movable steering cannot rotate freely, check whether there is corrosion or dirt at the ball. If equipped with fixed casters, ensure that the caster brackets are not bent.

3. Lubricant maintenance: Lubricate the casters regularly, and the wheels and movable bearings can be used for a long time. Applying grease to the frictional parts of the wheel axle and ball bearing can reduce friction and make the rotation more flexible. Under normal circumstances, lubricate the wheels every six months. The wheels should be lubricated every month.

In short, a good repair and maintenance of the casters can prolong the service life of the casters. However, if the casters are indeed damaged and cannot be repaired, they should be replaced in time. Because the price of the casters is not high, replacing the casters in time may be more than repairing the casters. Good deal!